Project:

Route Automation

Ninja Van has high operational costs in its warehouses, with Last Mile costs being six times higher than First Mile. This project began with the hypothesis that implementing a more efficient routing and sorting process could enhance productivity and reduce the manpower cost required for operations to run.

Company:

Vertical:

Ninja Van

Operations

Product Manager:

Designer:

Tech Lead:

Nicole Gan

Carissa The

Thunghan Hee

Serene Khor

Project type

A routing process that reduced warehouse operations cost by 50%

My roles and responsibilities

Led end-to-end UX process: scoping, discovery, and delivery; collaborating cross functionally to conduct research-backed trials to drive business impact.

1. Gather information from the ground to get real time visibility (Alongside 1 PM)

2. Identify patterns from historical data

3. Do end-to-end UX: Scoping, discovery and defining/refining/delivery for product concept and flows

4. Conduct multiple proposal and sharing to the wider teams based on research insights

5. Collaborate with vertical tech leads for concept trials to experiment on

6. Present proposals and insights to stakeholders; both local and regional to gain support for multiple region rollouts

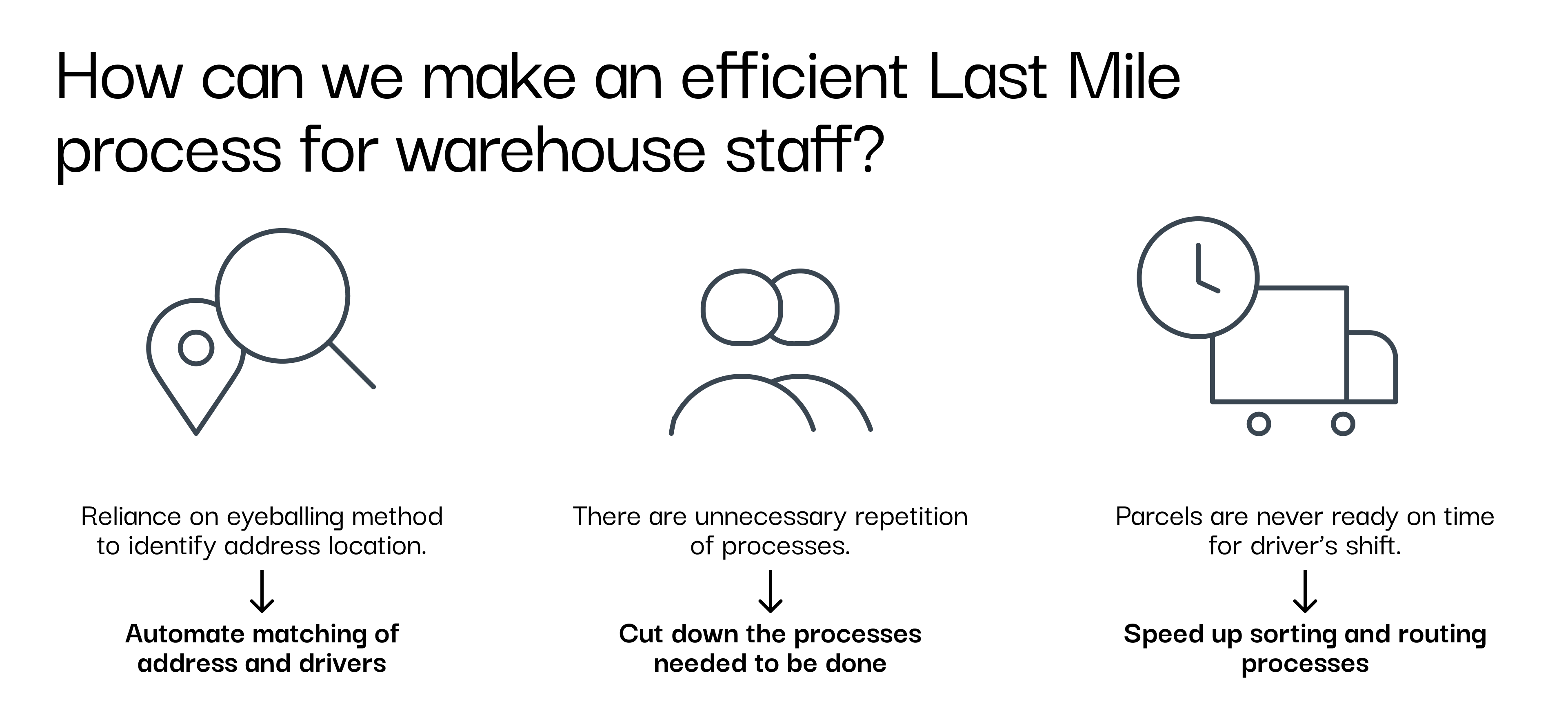

Problem

Last mile operational costs is 6x that of first mile.

Goal

Reduce manpower cost in Last Mile warehouse by 50% through productivity improvements, enabling the operation to run with fewer staff.

Within Last mile cost, manpower costs accounts for 40% of warehouse cost. vs. Average manpower costs for logistics operations should be in between 10-25%

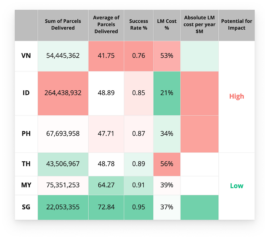

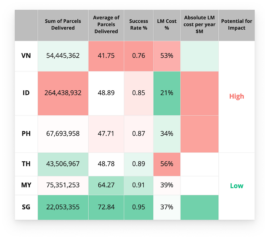

Focusing on Philippines — Prioritizing efforts on the most impactful areas, while recognizing that not all of the six operating countries are equal, From the data it is seen that Indonesia and Philippines spends the most for Last Mile cost, however Philippines delivers less than half of the volumes Indonesia handles, but spends the same amount of cost.

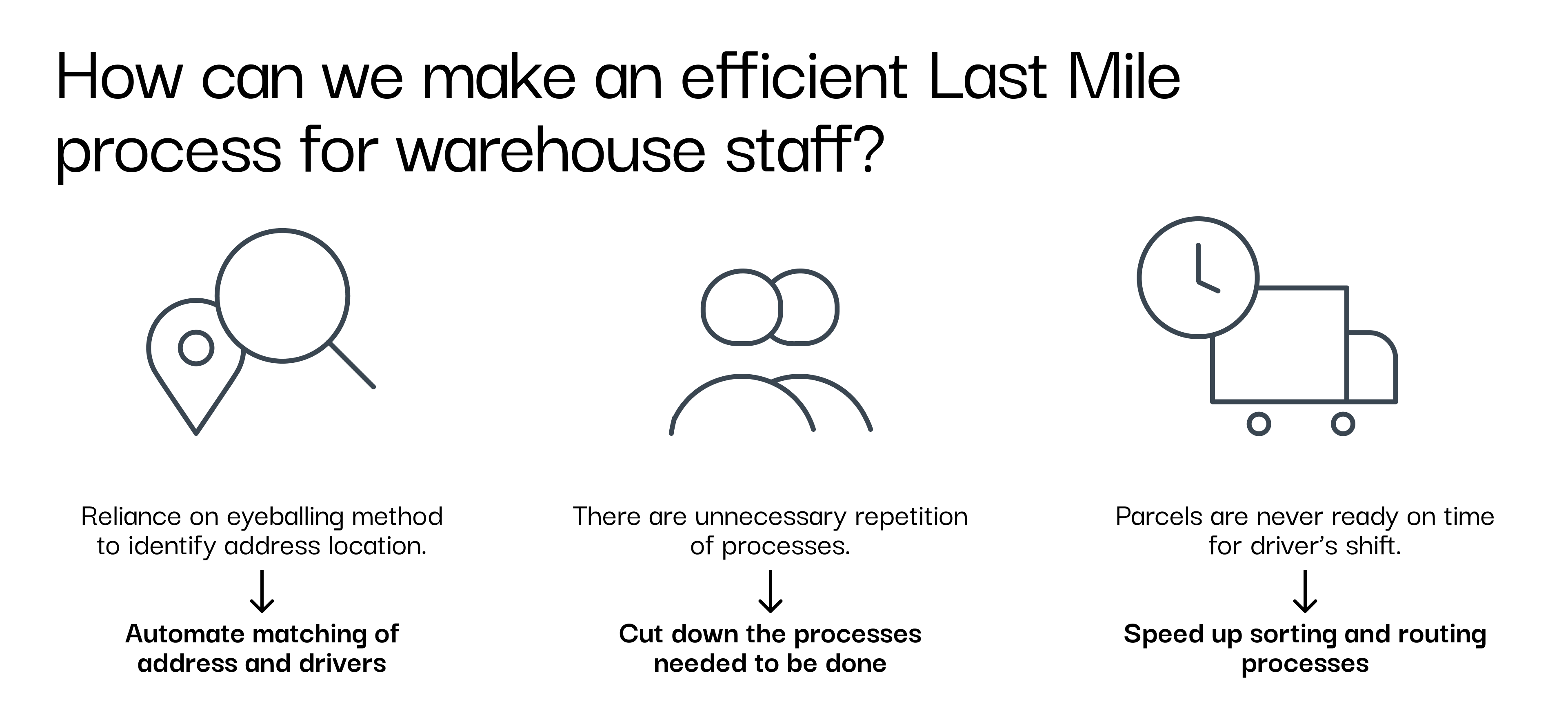

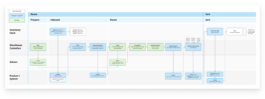

Decoding ground operations — Existing documentation was outdated and most information about Last Mile processes came through word of mouth with no clear source, we needed to see the ground operations firsthand. To get a clearer picture, we worked directly with warehouse staff from five stations in the Philippines to co-create a service blueprint—taking into account parcel volumes and urban vs. rural differences—to spot inefficiencies and find ways to improve efficiency.

MVP experiment

We needed to achieve what we set out to do in the cheapest and fastest way possible. This included a trip to select stations in Philippines where we trialed out our routing flow proposal.

Making it happen

This was the moment things got real—we found out we’d have the opportunity to head to the Philippines to test an experiment. However, this must be done in 2 weeks due to logistics planning.

With such a tight timeline, we needed a quick and low-cost way to validate the process. In Operations, real-time results are critical, so whatever we tested had to be used in an actual sorting and routing process.

Fast and dirty — OPV2, the internal Operations tool, is infamous for its reliance on CSV uploads, which became the foundation for our MVP idea — a Gsheet script that can match drivers with addresses; requiring minimal engineering resources, while being practical for use in a live setting.

Revised flow for efficiency gains — During the experiment in the Philippines, we tested the proposed flow, which serves as the blueprint for the process. The green sections indicate the parts that have been automated using a GSheet script.

What's next?

In the next phase, the process is integrated into internal tools to ensure data is collected for tracking and future innovation.

Following the experiment’s success, Ops pushed for wider adoption, but since the GSheet script was only meant for experimentation—not scale—it needed to be replaced to prevent operational issues. This phase is ultimately about maintaining and scaling Operations effectively.

Takeaways

From the initial conception, and the result shown — this was a project that showcased to the wider organization what grounded research and data analysis can deliver.

Understanding Business Value as a Designer — For me, being an effective designer means constantly questioning the value design brings. Through this experience, I’ve realized that strong design decisions do more than just enhance usability—they drive measurable business impact and facilitate meaningful conversations across teams.

Guiding Stakeholders to See the Impact — When faced with a vague brief, I believe the best approach isn’t to wait for direction but to actively engage in shaping the problem and defining what success looks like. In this initiative, I was able to demonstrate the power of open collaboration between business and product, reinforcing that designers are not just pixel pushers—we’re problem solvers who contribute to strategic outcomes.

Project:

Route Automation

Ninja Van has high operational costs in its warehouses, with Last Mile costs being six times higher than First Mile. This project began with the hypothesis that implementing a more efficient routing and sorting process could enhance productivity and reduce the manpower cost required for operations to run.

Company:

Vertical:

Ninja Van

Operations

Product Manager:

Designer:

Tech Lead:

Nicole Gan

Carissa The

Thunghan Hee

Serene Khor

Project type

A routing process that reduced warehouse operations cost by 50%

My roles and responsibilities

Led end-to-end UX process: scoping, discovery, and delivery; collaborating cross functionally to conduct research-backed trials to drive business impact.

1. Gather information from the ground to get real time visibility (Alongside 1 PM)

2. Identify patterns from historical data

3. Do end-to-end UX: Scoping, discovery and defining/refining/delivery for product concept and flows

4. Conduct multiple proposal and sharing to the wider teams based on research insights

5. Collaborate with vertical tech leads for concept trials to experiment on

6. Present proposals and insights to stakeholders; both local and regional to gain support for multiple region rollouts

Problem

Last mile operational costs is 6x that of first mile.

Goal

Reduce manpower cost in Last Mile warehouse by 50% through productivity improvements, enabling the operation to run with fewer staff.

Within Last mile cost, manpower costs accounts for 40% of warehouse cost. vs. Average manpower costs for logistics operations should be in between 10-25%

Focusing on Philippines — Prioritizing efforts on the most impactful areas, while recognizing that not all of the six operating countries are equal, From the data it is seen that Indonesia and Philippines spends the most for Last Mile cost, however Philippines delivers less than half of the volumes Indonesia handles, but spends the same amount of cost.

Decoding ground operations — Existing documentation was outdated and most information about Last Mile processes came through word of mouth with no clear source, we needed to see the ground operations firsthand. To get a clearer picture, we worked directly with warehouse staff from five stations in the Philippines to co-create a service blueprint—taking into account parcel volumes and urban vs. rural differences—to spot inefficiencies and find ways to improve efficiency.

MVP experiment

We needed to achieve what we set out to do in the cheapest and fastest way possible. This included a trip to select stations in Philippines where we trialed out our routing flow proposal.

Making it happen

This was the moment things got real—we found out we’d have the opportunity to head to the Philippines to test an experiment. However, this must be done in 2 weeks due to logistics planning.

With such a tight timeline, we needed a quick and low-cost way to validate the process. In Operations, real-time results are critical, so whatever we tested had to be used in an actual sorting and routing process.

Fast and dirty — OPV2, the internal Operations tool, is infamous for its reliance on CSV uploads, which became the foundation for our MVP idea — a Gsheet script that can match drivers with addresses; requiring minimal engineering resources, while being practical for use in a live setting.

Revised flow for efficiency gains — During the experiment in the Philippines, we tested the proposed flow, which serves as the blueprint for the process. The green sections indicate the parts that have been automated using a GSheet script.

What's next?

In the next phase, the process is integrated into internal tools to ensure data is collected for tracking and future innovation.

Following the experiment’s success, Ops pushed for wider adoption, but since the GSheet script was only meant for experimentation—not scale—it needed to be replaced to prevent operational issues. This phase is ultimately about maintaining and scaling Operations effectively.

Takeaways

From the initial conception, and the result shown — this was a project that showcased to the wider organization what grounded research and data analysis can deliver.

Understanding Business Value as a Designer — For me, being an effective designer means constantly questioning the value design brings. Through this experience, I’ve realized that strong design decisions do more than just enhance usability—they drive measurable business impact and facilitate meaningful conversations across teams.

Guiding Stakeholders to See the Impact — When faced with a vague brief, I believe the best approach isn’t to wait for direction but to actively engage in shaping the problem and defining what success looks like. In this initiative, I was able to demonstrate the power of open collaboration between business and product, reinforcing that designers are not just pixel pushers—we’re problem solvers who contribute to strategic outcomes.